Do engineers do hands-on work? Some engineers constantly work with their hands, while others may never touch a tool in their entire careers.

But let me tell you, when given the chance, I think every engineer should dive into hands-on work. I mean, getting out of that cozy office and heading to project sites, factories, and manufacturing plants. Then, rolling up your sleeves and using tools like wrenches, or at the very least, seeing the real world through your own eyes.

Without that first-hand engineering experience, you’ll never truly unlock your full potential as an engineer. To really hit this idea home, let’s chat about the importance of hands-on skills for engineers.

Important Note: There are certain jobs where you won’t interact with the physical world, and in those cases, hands-on work might not be super beneficial. For example, think about software development or some chemical engineering roles.

However, even if just a tiny 5% of your job involves the physical world, I firmly believe you’d be shortchanging yourself as an engineer if you never gained hands-on experience.

Real-world experience as an engineer

You know, sometimes engineering designs may look flawless on paper, and you might feel like an absolute genius. But remember, what’s really important is a design’s practicality, not just how pretty it looks.

Imagine this – you design an underground conduit without any protective encasement right at a river’s edge. On paper, it looks perfect, right? But in reality, the unstable soil would jeopardize the conduit during installation, causing it to snap under the pressure of the mud and rushing water. Without seeing the force of moving water on nearby soil, you’d never have known this.

The smarter move would be to run the conduit a safe distance away from the river.

With hands-on experience, you can learn what a successful design looks like while sharpening your common sense. Talk about a win-win!

In my opinion, real-world work experience is worth its weight in gold compared to formal education. It’s the express lane to understanding good and bad design. Plus, this experience ties together all those concepts you’ve studied in textbooks.

Think of it like reading about how to shoot a basketball through a hoop. Until you actually take a shot, you’ll never really learn. Even if you read every basketball book out there, someone who’s been practicing for just a month will outshine you if you haven’t tried it yourself.

My journey as a power engineer

Back in the day, I thought devouring tons of books on power engineering in my spare time would be enough to grasp it all. I figured mastering the theory would make me a design superstar. Boy, was I in for a surprise!

As a rookie engineer, I quickly realized I barely knew anything. Half the time during my design work, I found myself puzzled, wondering, “How am I supposed to know any of this? No one ever taught me this stuff!”

It was only by leaning on the wisdom of senior engineers and visiting project sites that I gained the insight I needed. Suddenly, a lightbulb flicked on, and I understood why I had to design a certain way. I realized that poring over schematics in books could only take me so far.

It’s like trying to whip up the perfect spaghetti and meatballs when you only know how to cook spaghetti. Reading a million meatball recipes won’t help you nail it!

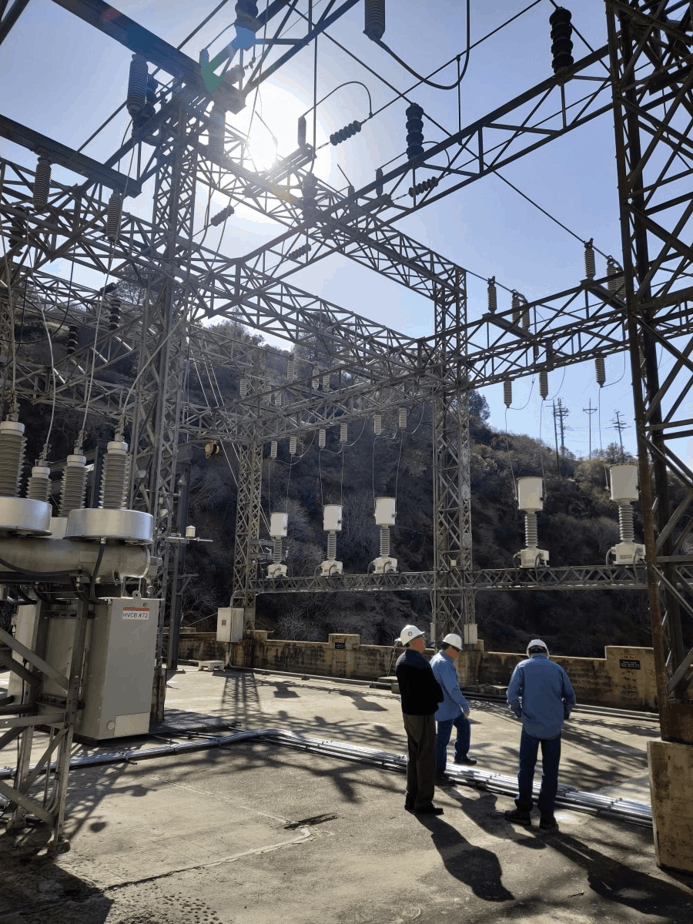

But here’s the real game-changer: I learned even more when I shadowed pros like journeymen, technicians, and construction workers at project sites. Watching them effortlessly tackle projects blew my mind and opened up a whole new world of engineering.

So, blending real-world skills and textbook theory helped me take my engineering game to the next level.

Engineering problems from lack of real-world experience

Take ground rods, for example – a seemingly simple issue that engineers often run into. Ground rods connect your electrical system’s ground systems to good ol’ Mother Earth. The National Electrical Code (NEC) says this about ground rods:

“The electrode shall be installed such that at least 2.44 m (8 ft) of length is in contact with the soil. It shall be driven to a depth of not less than 2.44 m (8 ft)…”

But here’s the catch – I often find ground rods installed flush with the ground, which might meet the code but isn’t the best engineering practice. Why? Because the ground we walk on naturally erodes over time. After a wet and wild winter season, the ground rod will eventually poke through the soil and become exposed.

This just goes to show that engineers can’t solely rely on textbooks or codes and standards. They won’t cover every curveball life throws at you, and they can only guide you so far. As an engineer, you need to dream up potential problems on your own by understanding the real-world limitations and issues.

Important Note: As an engineer, it’s not your job to install ground rods. But getting the lowdown on real-world problems and limitations will make you a better design engineer. When you’re privy to the potential issues with ground rod installation, you can specify exactly how you want the ground rod to be installed for your project.

Expectations from others on your hands-on ability

How can you tell someone to do something impossible with their hands if you can’t even do the basics yourself? If you design something that’s a nightmare to install, the machinist or contractor will think you’ve got a few screws loose. As a mechanical engineer, imagine designing a nut placement where a wrench won’t fit.

I’ve had projects where I was the only tech-savvy person on site, figuring out why a device I designed wasn’t working in a control panel or why a high-voltage piece of equipment I designed set off alarms. It’s tough and nerve-wracking but also a blast when you put your creativity and skills to the test.

The bottom line is, you gotta know your way around your own designs. It’s what people expect of you. Plus, being a jack of all trades makes you less likely to get the ax during job cuts.

NASA’s Apollo 11 Mission to the Moon

Werner Von Braun was a total genius of the twentieth century. He was the mastermind behind the development of modern rockets. He led the development of the Saturn V rocket, which let humans shoot for the moon.

Now, what’s this got to do with engineers and hands-on work?

Von Braun headed the rocketry team at the Langley, Virginia research lab. He told his colleagues to,

“keep their knowledge up to date and judgment sharp by keeping their hands dirty at the work bench.”

Similarly, Robert Gilruth, the engineer behind the Apollo 11 mission, remarked,

“I do not want to have our people, our engineers, sit in their offices and only look at paper. I want them to get their hands dirty, understand the hardware, bring it here and test it.”

Landing humans on the moon has got to be the most jaw-dropping engineering feat in history, a crazy combo of engineering breakthroughs all bundled into one mission.

The bigwigs behind the program knew that hands-on experience was essential for tackling the enormous challenges. Engineers had to roll up their sleeves and get down to business to unlock their full potential.

Only then could they craft practical space vehicles, fit to safely shuttle humans to the moon and back.

NASA’s deep belief in hands-on work

NASA’s passion for hands-on work goes way beyond the Apollo 11 mission. Here’s what they think hands-on work brings to the table:

- Deep understanding: You get up close and personal with your subject, making it easier to fine-tune future designs.

- Increased engagement: Seeing and touching your creations keeps you hooked, helping you remember more details.

- Sharpened skills: Merging theory and the real world turns you into a design wizard, adept at tackling problems head-on.

- Intuitive knowledge: You develop the ability to recognize successful designs from poor, making it easier to spot potential design disasters.

The most valuable engineering lessons come from those who push the boundaries of technology, and it’s even more valuable if they succeed. NASA and its contractors have been doing amazing things in terms of innovation and success, so taking their advice on hands-on work can only do you good.

Now, it’s true that computers do a lot of the heavy lifting in engineering these days, reducing the need for hands-on work. But as long as we’re living in the real world, hands-on work will always be crucial for crafting practical designs that solve real-world problems.

“Do engineers do hands-on work?” wrap up

Some engineers get their hands dirty, and some don’t. It really depends on your engineering specialty and your job. But when the opportunity arises, all engineers should dive in.

I’m not saying you can’t be an amazing engineer without hands-on experience. But you’ll never unlock your full potential without it.

So, make the effort to examine, touch, and witness successful designs in action. It’ll finally help you bridge the gap between what you’ve read in textbooks and what you can see in the real world.

In the end, stepping out of your office and into the field is one of the best moves you can make. It’ll help you max out your engineering prowess and gain rock-solid confidence in your work.

What do you think – is hands-on work a game-changer for engineers? For design engineers, which is more important: learning theory or hands-on work?

Featured Image Photo Credit: NASA (image cropped)

Author Bio: Koosha started Engineer Calcs in 2019 to help people better understand the engineering and construction industry, and to discuss various science and engineering-related topics to make people think. He has been working in the engineering and tech industry in California for well over 15 years now and is a licensed professional electrical engineer, and also has various entrepreneurial pursuits.

Koosha has an extensive background in the design and specification of electrical systems with areas of expertise including power generation, transmission, distribution, instrumentation and controls, and water distribution and pumping as well as alternative energy (wind, solar, geothermal, and storage).

Koosha is most interested in engineering innovations, the cosmos, sports, fitness, and our history and future.