NASA engineering has rocketed us to the moon and back. Heck, NASA’s Apollo program has blessed engineers with 5 invaluable mindset lessons.

These lessons showcase the rockstar mindset needed to pull off astonishing engineering wonders. And let’s not forget the most legendary of them all – the 1969 Moon landing.

So, let me spill the beans on what engineers can learn from NASA’s Apollo program to seriously up their game.

Important Note: NASA’s Apollo program aimed to land humans on the moon and bring them back. Apollo 11 marked the first of these moon-landing missions.

For the Apollo missions, NASA engineers did loads of the engineering. But also, many third-party engineering firms lent a hand.

#1 Design around every last constraint

As engineers, we wrestle with real-world constraints set by Mother Nature. But we also play by the rules of the engineering code of ethics.

In NASA’s race to the Moon, the list of constraints was ridiculously long. So much so, it makes Columbus’ voyage across the ocean in a wooden ship look like child’s play.

The tech from 1969 seems totally alien to us today. Just check out your Apple iPhone. It’s packing 100,000 times more processing power than the computers used in the Apollo 11 mission.

Despite the challenges, engineers safely sent humans to the Moon on board a freaking missile. The rocket given this mammoth task was the Saturn V. This monster was a whopping 363 feet tall and weighed 6,200,000 pounds!

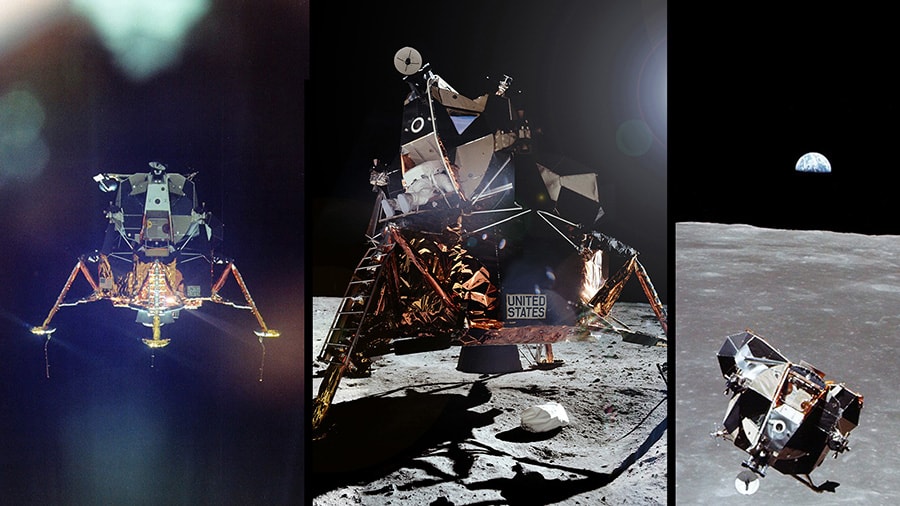

The Saturn V launched Neil Armstrong, Edwin “Buzz” Aldrin, and Michael Collins to the Moon. In its launch, it also hauled the following mission-critical spacecraft into space:

- Command Module Columbia

- Service Module

- Lunar Module Eagle

The design constraints of the Apollo 11 mission

This was truly an achievement for the ages. To pull off this engineering miracle, NASA engineers tackled constraints like:

- Cost: staying within their $20 to $40 billion budget.

- Distance: traveling 238,900 miles to the moon. Prior to these missions, the highest altitude reached was a mere 100 miles.

- Specs: meeting all equipment operational specs, both on Earth and on the Moon.

- Materials: shielding humans and electronics from radiation and extreme temperatures.

- Navigation: ensuring high-precision navigation to land on the Moon.

- Fuel management: limiting fuel consumption to minimize spacecraft weight, yet still making the round trip.

- Amenities: catering to astronauts’ every need in a tiny spacecraft, including oxygen, water, food, clothing, and even a bathroom, all while providing necessary flight and work equipment.

Faced with these constraints, NASA engineers remained unflappable and optimistic. They viewed more constraints as simply a more intriguing and challenging puzzle. As one NASA engineer, Guy Thibodaux, put it,

“It was the greatest place to work in the world.”

In the end, NASA engineers left no stone unturned. They thoroughly studied every constraint in their design stage. So, the takeaway is: no matter your project’s size, learn and thoroughly understand every single constraint. That’s the key to success.

#2 Rally around a single solution and bring the team together

As engineers, we often find ourselves with a whirlwind of ideas swirling in our minds. It’s rare for the perfect solution to just pop into our heads, making us shout, “Eureka! This is it!”

Instead, we dive into a creative process, whip up a design, and after some solid analysis, we commit to one solution and run with it. Otherwise, we’d be wasting precious time, running around in circles without making headway.

The story of how the U.S. outdid the Russians in the race to the Moon is a prime example. It all kicked off with President Kennedy’s speech to Congress on May 25th, 1961. He rallied for human exploration of the moon, and suddenly, the mission became crystal clear to everyone, from politicians to NASA leadership and engineers.

That same year, Wernher von Braun, a prominent space industry figure and rocket pioneer, made a statement. As the director of NASA’s Marshall Space Flight Center and the chief architect of the Saturn V rocket, von Braun said Kennedy’s speech “puts the program into focus…Everyone knows what the moon is, what this decade is, what it means to get some people there.”

In short, the U.S. became laser-focused on the Moon mission, which galvanized engineers to work together enthusiastically.

The fusion of engineering brainpower at NASA

It didn’t take long for NASA engineers to choose one design option for the mission. In 1963, the Apollo program settled on using a Saturn V rocket to launch three men in a Lunar Orbit Rendezvous (LOR). Now, the only discussion was how engineers would execute this plan.

In contrast, the Russians struggled with cohesion in their engineering efforts. The brilliant minds of Korolev, Glushko, Chhelomei, and Yangel never agreed on a single design, preventing them from collaborating effectively.

In engineering, many minds are usually better than one—but only when everyone can eventually get on the same page. This highlights the importance of single-mindedness in engineering efforts.

So, the lesson here is to put your ego aside and collaborate with your fellow engineers. The ultimate goal is to execute a single mission in the most efficient and effective way possible.

#3 Break down problems to their core

In the real world, engineering problems aren’t just black and white. They’re a messy jumble of variables with a bunch of missing puzzle pieces. But great engineers don’t let that get them down. Instead, they dig deeper and think outside the box to find solutions.

Before 1969, no country had sent humans to the Moon. So, NASA engineers first had to outline all the problem parameters, as we talked about in Lesson #1. Then, they figured out what existing tech they could use and what they needed to invent.

To do this, NASA engineers broke the mission down to its bare bones. This stage of the design was crucial because even the tiniest hiccup could lead to mission failure.

Now, not all engineers will be sending humans to outer space. But it’s crucial to always break problems down to the nitty-gritty. That way, you’ll know the variables you need to tackle. This lesson follows the first principles thinking popularized by Elon Musk.

The design of the Apollo astronaut spacesuit

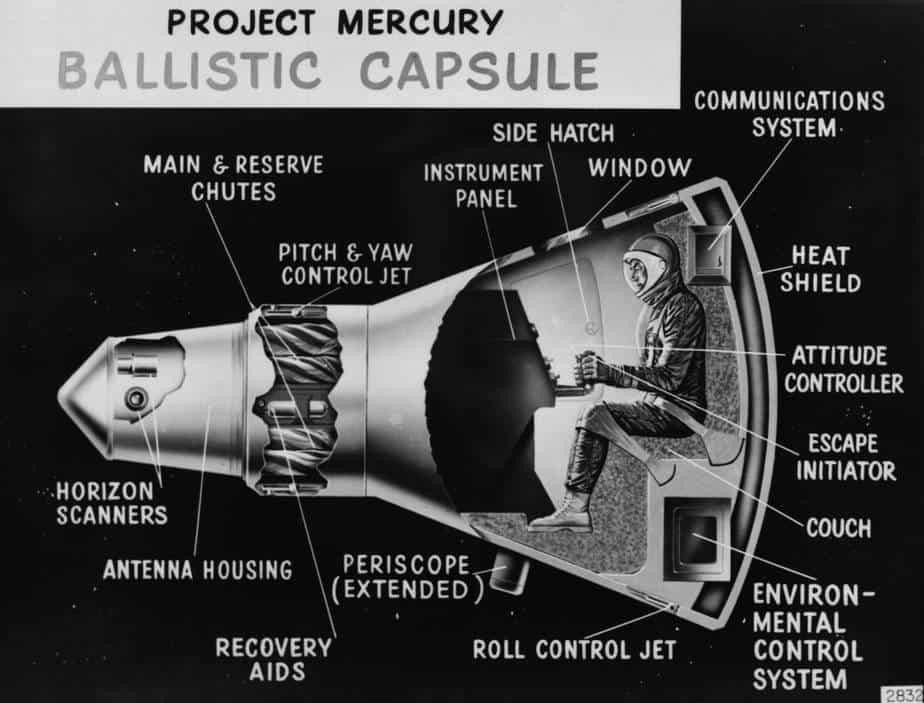

The goal of NASA wasn’t to just land on the Moon. NASA wanted astronauts to step foot and walk on the Moon. So, NASA put out a proposal for bids for the development of the Apollo spacesuits. Spacesuits are like mini spacecraft used to protect astronauts from the dangers found in space.

So not surprisingly, the development was far from easy. Plus, the specs for the spacesuits were extremely long and involved. The company with the winning bid had to design around the following spacesuit specs:

- Provide enough pressure to keep body fluids in a liquid state

- Supply oxygen and remove carbon dioxide

- Maintain a comfortable temperature

- Allow flexibility for human joints

- Allow finger mobility to handle tools

- Protect against meteor dust

- Omit flammable materials

- Maintain minimal suit weight

What’s more, many of the initially submitted suits failed a critical fall test. Astronauts had to fall on their backs and try to stand back up. Because the last thing you want is to fall back like a turtle on its shell and be stuck on the Moon.

#4 Own your work and take full responsibility

You know, most Apollo program engineers really owned their work. They took full responsibility for their assigned tasks, and that level of ownership was key to the success of the moon landing.

In July of 1969, each and every engineer held their breath as Apollo 11 blasted off. Depending on their roles, engineers kept a close eye on their contributions, nervously monitoring things like:

- Fuel supply calculations for the round trip to the moon

- Engine performance for reaching, landing, and taking off from the Moon

- Computer code guiding the spacecraft

- Amenities in the spacecraft keeping astronauts alive

- Moon’s gravity calculations for planned spacecraft operations

Engineers knew that even a misplaced screw could spell disaster. So, they scrutinized every last detail as if their lives depended on it. This was NASA’s work culture, and it created high-performing engineers.

The takeaway here is, don’t expect others to pick up your slack. When you’re given a task, crush it to the best of your ability. It’s not fair to other engineers who have to pick up your pieces, and you’ll miss out on learning and growing. Even worse, this is how engineering failures happen.

#5 Stay optimistic against all odds

In engineering, challenges and frustrations are par for the course, especially when you’re working on the cutting edge of technology. So, it’s crucial to stay optimistic and power through those dark moments.

For the Apollo missions, engineers had to figure out how to get a 6.2 million pound fully fueled rocket off the ground. This meant designing mind-blowing rocket engines, 10 times more powerful than any U.S. rocket ever built. Enter the F-1 engines.

The Saturn V used 5 of these bad boys for the first stage of the mission. Each engine would pump out a whopping 1.5 million pounds of thrust, guzzling 3 tons of fuel and oxidizer every second!

But how do you develop such a beast of a rocket engine? Some engineers thought scaling up existing rockets would do the trick. However, early tests didn’t go as planned. Engines exploded during testing due to combustion instability, and the engines were just too darn big, causing all sorts of operational issues.

This shook NASA to its core, leading to doubts about whether the engines could even scale up. But engineers stayed optimistic.

The redesign of the F1 rocket engine

NASA engineers tinkered with various engine design adjustments, such as:

- Nozzle shape

- Orifice diameter

- Fuel and oxidizer entry angles

- Fuel and oxidizer entry pressures

- Gas rotation speed

After a relentless series of design changes, the engine finally delivered the goods. The grueling work took one and a half years and thousands of engineering hours, not to mention 78 hours of live engine testing.

Without optimism, though, this redesign wouldn’t have been possible. One solution didn’t magically fix all the issues. Instead, small design improvements built on each other. This also underscores the importance of hands-on experience for engineers.

The lesson here is to stay optimistic despite the challenges you face. If not for optimism, who knows, we might still be living in caves!

Conclusion

The success of the Apollo program was nothing short of an engineering masterpiece. The program showcased the incredible mindset of its engineers, proving that a strong mindset is essential for staying at the top of your game in engineering.

World-changing accomplishments don’t happen by luck. They require awesome teams of people who share the same mindset and vision.

What’s your biggest takeaway from NASA engineering with the Apollo program? Do you think mindset is what separates average engineers from great engineers?

Featured Image Photo Credit: NASA (image cropped)