How to check engineering drawings? It’s all about doing detailed self-reviews, getting third-party feedback, and building good review habits.

I’ll share with you my 8 go-to techniques for reviewing engineering drawings. These tips will not only turbocharge your review process but also give you peace of mind knowing that your clients can trust your work for years to come.

#1 Self-review drawings

So you’ve wrapped up your design drawings, nice work! Now it’s time for a breather. Set them aside for a day or two before diving back in for a review. This mini-break lets you tackle them with a fresh perspective, making it easier to spot any sneaky mistakes.

Keep these tips in mind while reviewing:

- Give every drawing your full attention, even if it looks simple.

- Print your drawings on large sheets – mistakes love to hide on computer screens.

- Choose a quiet spot for reviewing, free from distractions.

- Jot down any design elements you’re not 100% sure about.

With your name on those drawings, it’s up to you to put in the elbow grease during the review. Don’t bank on someone else doing the heavy lifting for you. Remember, you’ve gotta stick to that engineering code of ethics.

Think of it like putting together a crib for your newborn. You’d definitely follow the instructions down to the last detail, triple-checking that all screws are snug and secure.

#2 Yellow line drawings

In engineering, designs are often a complex web of interconnected elements. That’s where yellow-lining comes to the rescue! With this nifty trick, you’ll be able to cross-check related drawing elements in a snap.

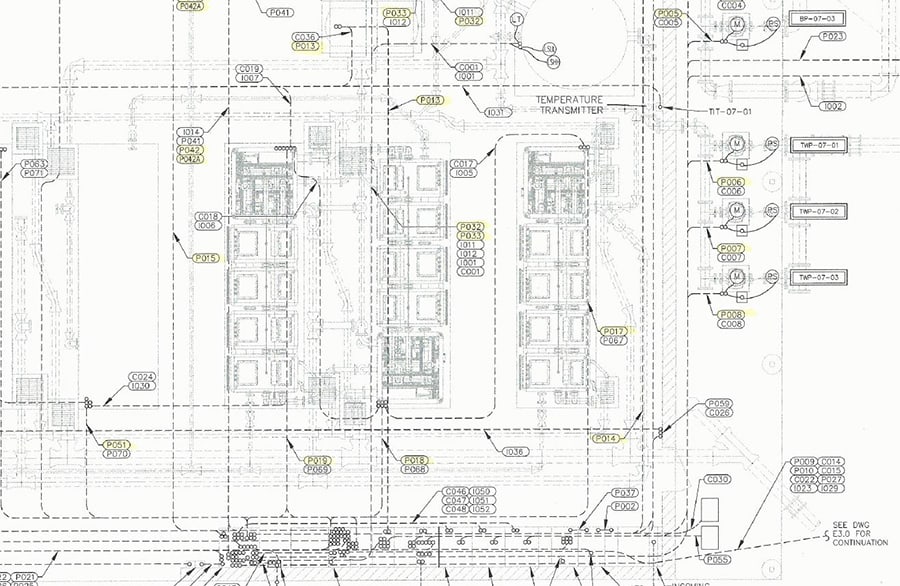

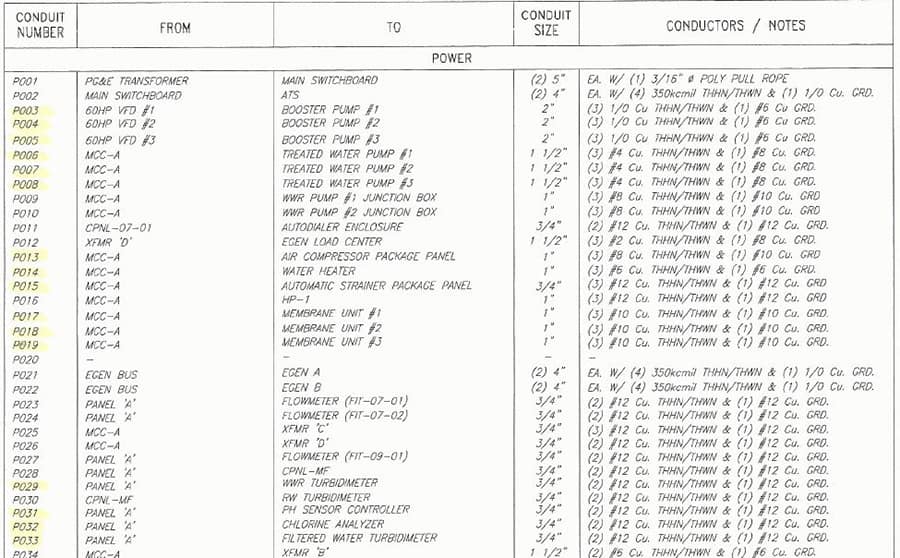

For example, in electrical drawings, a conduit schedule and a site plan go hand in hand. The site plan shows tagged conduits running from point A to B, while the conduit schedule lists those very same tagged conduits, with a bit more detail.

Grab a highlighter and cross-check conduit tags from the conduit schedule against the site plan, verifying the routing and fill. If you accidentally label a conduit incorrectly on the site plan, the contractor could use the wrong conduit size and fill.

Here’s a quick example of a site plan and conduit schedule I’ve yellow-lined.

Site plan:

Conduit schedule:

#3 Create a standard drawing review checklist

Every engineering discipline shares some common checklist markers when it comes to reviewing drawings:

- Codes & standards

- Calculations

- Vendor cut-sheets

- Formatting

- Real-world application

Make sure to check these elements in your drawings. Let’s dive into each one to understand their importance.

Codes & standards

Identify all the codes and standards relevant to your design and look for any violations. Be sure to use the most up-to-date versions during your review—you don’t want to rely on a codebook from the 1990s.

With experience, you’ll get better at spotting compliance issues without having to flip through a massive codebook for every design.

Calculations

Double-check all your calculations and units, even the simplest ones. I’ve seen way too many basic math and unit errors that could’ve been easily avoided.

Remember, even a tiny mistake can snowball and wreak havoc on your entire design. That’s why it’s so important to review designs in stages.

Product cut-sheets

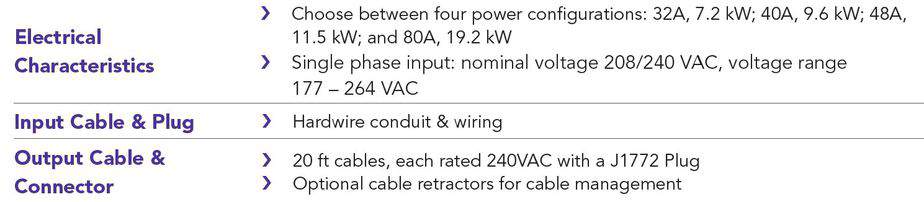

Verify your specified products against the latest vendor cut sheets for compliance. You want to be absolutely certain you’re using a product correctly.

For instance, if a cut sheet states a product connects at 240 volts but your design shows it connected at 480 volts, you’ve got both a code violation and a major safety concern on your hands.

Stay on your toes, even if you’ve used a product for years. Vendors can make sneaky updates, so always verify the cut sheet to dodge expensive mistakes.

Formatting

Don’t forget to check the format of your drawings—it’s just as important as proofreading a Word document. Keep these formatting aspects in mind:

- Line types: maintain consistency

- View orientations: ensure section views are correctly displayed

- Symbology: adhere to industry standards

- Appropriate border: use the right drawing title block

- Text: stay consistent with the project’s selected font size and type

- Scale: check listed scale matches with final drawing print size

Real-world check

Now, for the million-dollar question: will your designs actually work in the real world? A design might look flawless on paper, but if it’s unbuildable, you’re in trouble. So, when reviewing, channel your inner construction worker or manufacturer. This is when experience really comes in handy.

Keep these real-world checks in mind during your review:

- Geometric accuracy

- Buildability

- Laws of physics

#4 Coordinate with other engineering trades

In the majority of projects, various engineering disciplines join forces. That’s why it’s crucial to harmonize your design with your teammates. As the lead engineer, make a point to cross-check your work with your subcontractors. I’ve seen how one discipline’s tweaks can trigger mayhem when others are left in the dark.

Important Note: For each project, shoot an email requesting the most recent design info and use that for your work. This way, you’ll have a record of the latest and greatest info.

#5 Get a second opinion from a qualified engineer

Get a fellow qualified engineer on your team to give your drawings a thorough once-over. I can’t stress enough the importance of not sending out drawings without a second pair of eyes to review them.

No matter how long you’ve been an engineer or how fantastic you think you are, we all make mistakes—even the 10x engineers.

Just be certain that the other engineer is as skilled or even more so than you. Otherwise, you risk undermining the whole point of a peer review.

Helpful Tip: Use colored pencils to mark up drawings during a review. Try yellow for correct items, blue for comments, and red for errors. Or, find a color scheme that works for you and your team, and stick with it.

#6 Create a global review process

Develop an internal process for examining drawings. Make sure to include a list of checks that every drawing set must pass before leaving the building.

This creates a solid framework for everyone to follow, regardless of the project size. As a result, you’ll minimize design blunders.

Involving management in the review process

Ensure management supports the review process. This guarantees that everyone adheres to the review protocol for every single project.

Moreover, only include qualified individuals in the review process. If everybody chimes in, you’ll end up with a chaotic disaster. A design can be ripped to shreds by too many unqualified critics.

Important Note: If there’s any lingering doubt about a design element, give the designer the benefit of the doubt. After all, they’re the ones signing off on the drawings and taking on all the liability.

#7 Get a feel for top-notch drawings

I’ve learned so much about what outstanding drawings look like by examining old-school designs – I mean those hand-drawn masterpieces from the pre-CAD era. Surprisingly, these vintage gems often pack more detail than many modern-day drawings.

Now, I’m not saying those old-timers didn’t goof up. And, sure, design standards have come a long way in the last four decades. But those intricate details made the drawings a breeze to review and a cinch to follow. You don’t want someone cursing your name because they can’t make heads or tails of your drawings, do you?

#8 Handy tips for checking engineering drawings

Over the years, I’ve collected a bunch of nifty pointers that have come in real handy:

- Stick to one unit system, either Metric or English.

- Sketch out a rough design concept before reviewing someone else’s work, so you don’t inadvertently adopt their perspective and miss errors.

- Keep an eye out for number discrepancies in your documents, like showing Beam ‘A1′ as 10′ in one drawing and 20’ in another.

- Fill in all the blanks in your title block.

- If your company uses an error-checking system, see which mistakes pop up most often and learn from them.

- Show all the necessary equipment and product clearances.

- Include all vital equipment and product dimensions.

- Verify all physical dimensions.

- Cross-reference other drawings as needed to create a cohesive drawing set.

- On schematics, make sure symbols, reference designators, and polarity markings are on point.

- Don’t forget to proofread for spelling and grammar.

- Double-check all drawing notes for accuracy, as they’re often lazily copied from one project to the next.

Conclusion

Becoming a pro at checking engineering drawings is crucial for any engineer. Embracing best practices for reviewing drawings is the secret sauce to shining in your field and ensuring public safety.

What are your thoughts on checking engineering drawings? What’s your favorite technique for reviewing drawings effectively?