What do engineers do? Many folks think they just create cool gadgets, but their work is incredibly diverse and often cloaked in mystery.

You’ve likely seen engineers in movies, like Tony Stark—the badass engineer from Iron Man—tinkering with shiny new inventions. Tony codes software, develops electronics, and powers his suit with his engineering expertise, which probably spans mechanical, electrical, and software engineering. It’s no wonder Elon Musk compares himself to Tony Stark!

Now, engineering may not always look as flashy as Tony Stark’s work, but trust me—engineers are behind some jaw-dropping accomplishments. Sure, parts of the job can be a drag (been there, done that), but the fruits of their labor are all around you. Your phone, the plane soaring overhead, the car zipping by, and the internet—they’re all thanks to engineers.

Next time you’re awestruck by awesome movie gadgets, remember it’s just the tip of the iceberg. Behind the scenes, a whole bunch of engineers are grinding away, some in less glamorous roles, to make those innovations a reality.

The truth behind “what do engineers do?”

As a seasoned engineer with over a decade of experience in sunny California, I can give you the lowdown on what we engineers actually do.

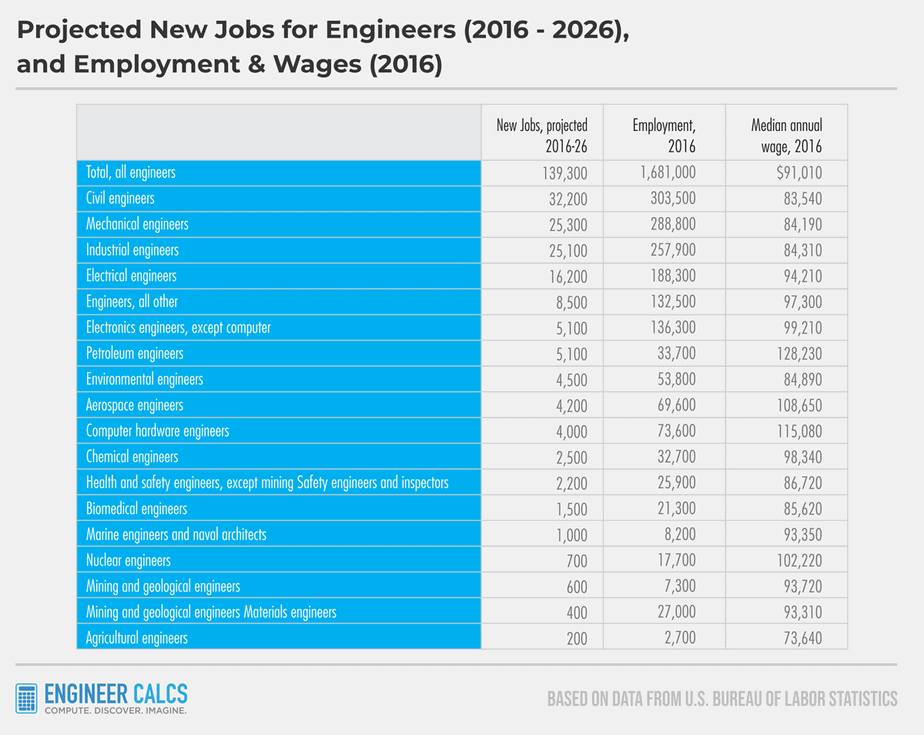

First off, there’s a whole bunch of engineers out there, with some specializing in design, research, or inspections, and others focusing on number-crunching or various tasks across all engineering disciplines.

I’m a consulting electrical engineer at a small firm, where I get my hands dirty with hands-on design work on different projects, unlike what I’d be doing at a larger company. Let me give you a peek at what my job involves, so you can decide if engineering is your jam. And if you do choose to go down this path, be sure to check out my article on how to become a stellar engineer or even a 10x engineer.

1) Finding engineering projects to work on

Engineering is all about making your ideas come to life through thrilling projects. But here’s the catch—you can’t work on projects without having them first. And let’s face it, projects don’t just fall from the sky. You need to hustle and build a solid rep to land them, and sometimes it feels like a battlefield competing against a horde of other firms.

At my firm, I spend about 6 to 8 hours a week whipping up project proposals and networking. Think of a project proposal like a resume and cover letter you send to an employer for a new gig. They use your resume and cover letter to decide if you’re the one they want to hire.

2) Job walks at project sites

To get the details of a project, I sometimes do a job walk with the owner. If we score the project as the prime consultant, we’d call the owner our client.

During a job walk, the owner spills the beans on the project to all interested parties. For instance, if a substation transformer needs replacing, I’d head to the site and grill the owner with questions like:

- Why are you replacing the transformer?

- Any design constraints I should be aware of?

- Do we need to bump up the transformer rating due to increased loads?

- How much downtime can we afford in the cutover phase?

- What’s the project timeline?

These questions help me get a better grasp on the project, which lets me whip up a killer project proposal.

For some projects, a 2-hour conference call might replace the job walk. It’s still about firms picking the owner’s brain to create the best proposal they can.

3) Design work – the heart of what engineers do

When you think about what engineers do, design work probably tops the list. Be it designing bridges, buildings, computer chips, planes—you name it.

But let’s be real, Hollywood often amps up the engineer lifestyle. You’ve seen those exhilarating movie scenes with engineers hidden in secret labs, crafting futuristic gizmos. I was captivated by them as a kid, too.

The reality, though, is that actual design work is a far cry from the movies. It doesn’t happen in the blink of an eye. Instead, the design process is a meticulously planned and executed series of steps, calling for the collaboration of many people across various engineering disciplines.

In my role, I collect info from the owner and other engineering disciplines to make sure my electrical design meshes perfectly with the overall project vision.

4) Construction Services

Once the design work is wrapped up, it’s time for the thrilling construction services phase! This is where the rubber meets the road, and I’m the maestro ensuring my design is flawlessly executed.

As the overseer, I juggle many roles. Most importantly, I’m the go-to person for answering RFIs (Request for Information) from the contractor. If they have questions or concerns about my design drawings or specs, I’m the one dishing out the info they need to move forward.

Another critical part of my gig is reviewing the contractor’s equipment choices during the submittal review process. It’s vital that their purchases align with what I’ve specified in my design.

But even the best-laid plans face unexpected twists in construction. That’s why I attend oodles of meetings and keep a watchful eye on the project. You never know when something like dinosaur bones will surface and throw everything for a loop!

And after the dust settles and construction is done, it’s time to compile the as-built drawings. I take the contractor’s marked-up design drawings, update the final set, and give the client a complete and accurate set of drawings.

5) Startup of a completed project

The true climax of a project is the successful startup testing, which happens only after construction wraps up. At this critical moment, I pack my bags and head to the project site to oversee the equipment’s startup. Everyone involved in the project eagerly awaits this moment, including equipment vendors and testing companies, who all gather to witness the equipment spring to life.

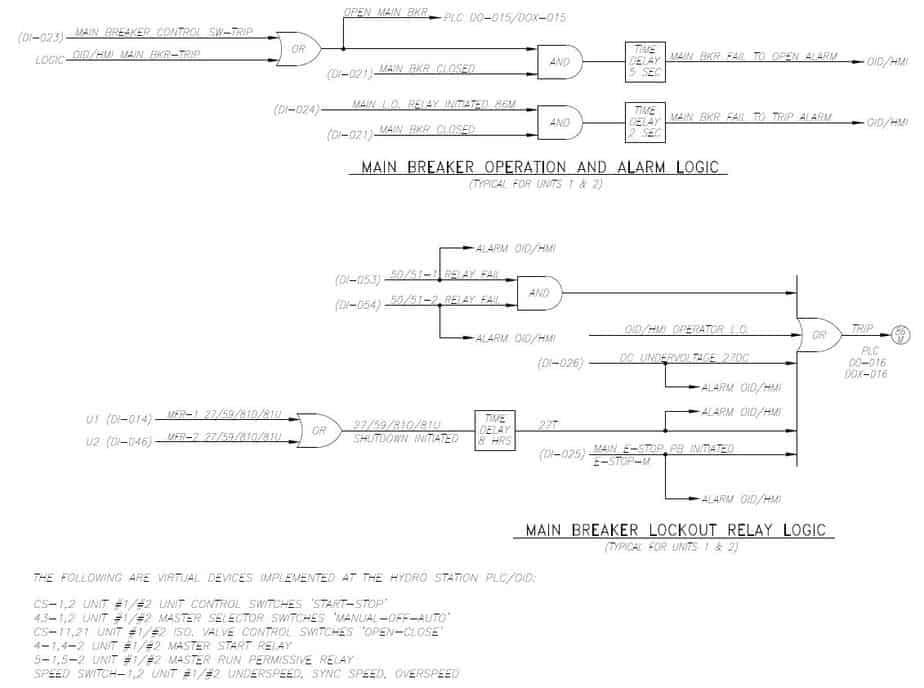

For example, in a hydroelectric project, we run various checks and tests during the startup phase. These include:

- Do the turbine and generator function properly?

- Do all the generator alarms trigger correctly?

- How effectively do the protective relays operate?

- Do all the pipe valves open and close when commanded?

Like the construction phase, the startup phase is a rollercoaster, and things don’t always go smoothly. You’ve got to be sharp, ready to troubleshoot any issues that pop up on-site pronto. But once I’ve given the green light for the successful completion of the startup testing, the project is officially a wrap from my end!

6) Handling billing and accounting

Every thriving business knows that cash is king. Without spot-on financial management, even the most promising ventures can nosedive fast.

That’s why I’m all business when it comes to handling billing and invoices for my clients. Be it tracking project budgets or requesting extra funds for out-of-scope work, I’m always on my A-game. And invoicing? I’m a die-hard perfectionist, dotting every “i” and crossing every “t” to ensure my clients get accurate and timely invoices tailored to their needs.

But let’s be real – some clients need a gentle push to pay their bills. Getting them to cough up on time can be a challenge, but it’s another critical part of playing the money manager. I’m always eagle-eyed for those who haven’t paid and ready to chase them down.

7) Downtime as an engineer

When I hit a lull in billable work, I call it downtime. Sometimes it stretches for weeks, while other times it’s just a day or two. Regardless, downtime is a chance to be productive in other ways.

During these moments, I like to:

- Hunt for exciting new projects online

- Strategize and seek out business opportunities

- Plunge into cutting-edge tech and hot-off-the-press technical subjects

- Organize my files and documents

In a nutshell, downtime lets me plan and learn for the future. It’s an unpredictable yet vital part of being an engineer, so I seize every opportunity to make the most of it and use my time wisely!

8) Lifelong learning for engineers

Engineering fields are ever-changing, and staying current with the latest advances is key to success. But who needs a dull classroom when you can dive into the excitement of self-learning? I believe that driven self-education trumps sitting in a lecture hall any day.

As an engineer, I crave knowledge. I gobble up the latest industry news, inventions, and regulations to deliver my clients the finest and most cost-effective designs. To think like a top-notch engineer, you need to be ahead of the game.

Here’s how I satisfy my curiosity:

- Magazine subscriptions: Yeah, who reads magazines these days? Well, I do! I relish the tactile experience of holding and reading certain magazines. The cherry on top? Some articles cover topics I’d never think to Google.

- Books: Reading is a passion of mine, and my booklist is ever-growing. Books help me sharpen my mind and learn new things, inspiring me to tackle fresh challenges.

- Equipment suppliers: When time permits, I invite equipment suppliers for an in-person presentation. They show off their latest gear, hoping I’ll use it in future projects. It’s a win-win for me and my clients. Plus, getting hands-on with new gadgets and gizmos is a blast!

In short, engineering isn’t just about crunching numbers and drafting blueprints. It’s about staying curious, fueling a passion for learning, and constantly seeking new knowledge.

What Do Engineers Do? Many Things!

Each of the 8 tasks I covered here could be a full-time job on its own. In one company, an engineer might focus on pitching and developing new projects. In another, they could be immersed in design work.

That’s why I encourage you to connect with someone already rocking it in your field of interest and ask them straight-up about their job. After all, media and professors don’t always paint the full picture.

And when you find a job type that revs your engine, don’t hold back! Floor it and chase your dreams full-throttle.

What kind of engineering work piques your interest? What’s your dream engineering job?

Congratulations for making it with engineering in your life….I’m a first year student at Namibia university of science and technology studing electronics and telecommunications engineering please i want you to tell me more about this course and specifically what i need to know.